How to Debug the flecker Control Valve 3900NXT

2025-03-10 10:00

FLECKER Control Valve 3900NXT Debugging Method, FLECKER 3200NXT Controller Chinese Operation Manual, How to Adjust the Parameter Settings of FLECKER Control Valves? Analysis and Solutions for FLECKER Multi-port Control Valve Water Softening Equipment Failures.

FLECKER Control Valve 3900NXT Debugging Method, FLECKER 3200NXT Controller Chinese Operation Manual, How to Adjust the Parameter Settings of FLECKER Control Valves? Analysis and Solutions for FLECKER Multi-port Control Valve Water Softening Equipment Failures.

American FLECKER control valves are divided into two types based on their application methods: electronic and mechanical. With the continuous development of market demand, the electronic type, known for its precise measurement, has gradually replaced most mechanical types. However, in recent years, our company has frequently encountered users who struggle with operating the control interface. To address these issues, ChiMay, with over a decade of experience, will explain "How to Debug the Imported FLECKER Control Valve Model 3200NXT?"

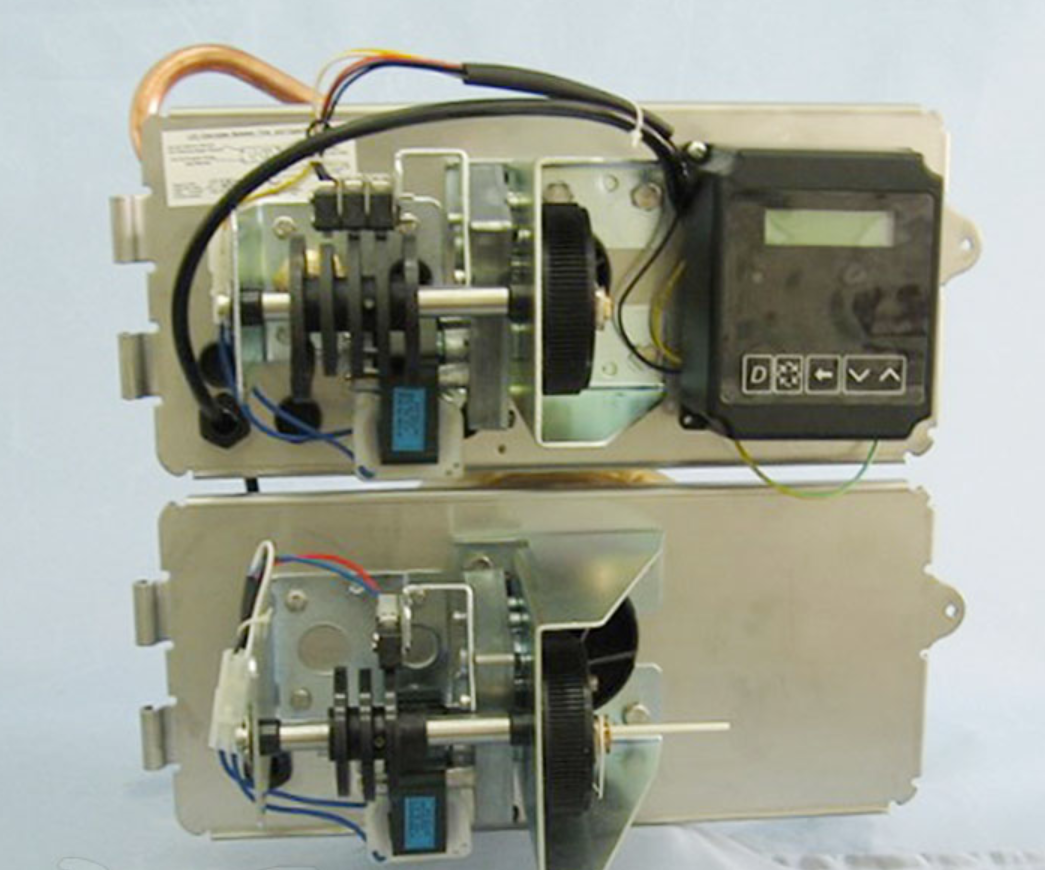

Overview of FLECKER Control Valve 3900NXT

The FLECKER 3200NXT is an essential component of multi-port control valves, featuring a microcomputer PLC-adjustable interface display. It is compatible with FLECKER multi-port valves such as the 2750, 2850, 2900, 3150, and 3900. When setting parameters for each matched multi-port control valve, adjustments must be made according to the valve model, and parameter values can be customized to meet user requirements. This electronic multi-port control valve can display numbers, flow rates, and the time required for regeneration programs. Compared to mechanical valve bodies, it offers more stable performance, convenient and reliable operation, and precise counting. It can also be equipped with remote devices based on user needs.

FLECKER 3200NXT Controller Setup and Debugging Methods

1. Setting the Current Time

Note: The time setting for the main and auxiliary valves must be within 10 seconds of the standard time.

-

Press and hold the up or down key for 2 seconds.

-

Press the move key to select the digit you want to change.

-

Use the up or down key to adjust the digit.

-

Press the cycle key to return to the normal display, or wait 5 seconds for automatic exit.

Note: Pressing the "D" key (diagnostic key) will exit without saving changes.

2. Manually Initiating a Regeneration

-

When the panel is in working status, press and hold the cycle key for 5 seconds.

-

The panel will advance to regeneration step 1, and the display will show the time for this step.

-

Press the cycle key once to advance to regeneration step 2.

-

Press the cycle key once to advance to regeneration step 3.

-

Press the cycle key once to advance to regeneration step 4.

-

Press the cycle key once to advance to regeneration step 5.

-

Press the cycle key once to return to normal working status.

Note: Pressing the cycle key for less than 5 seconds can clear a manually initiated or queued regeneration. Queued regenerations can only be cleared by manually initiating regenerations one by one. Any regeneration initiated before a queued delayed regeneration will cancel the original queued regeneration. Pressing the cycle key during regeneration will advance the regeneration step.

3. Panel Operation During Programming

When the panel is not in regeneration status, it will remain in standby or normal working program mode for a long time. In program mode, the control panel continuously monitors water usage. The control panel's program is permanently stored.

Operation During Power Outage: All programs are permanently stored. The current valve status, time for each step, and current time will be saved during a power outage and restored after power is resumed. The current time will be saved if the power outage does not exceed 12 hours.

Note: The current time on the main control screen will flash for 5 minutes after a power outage. Press any key to stop the flashing.

4. Interlock Control

The control panel will not allow the unit or system to enter regeneration unless the regeneration interlock signal has been released. The interlock line between units is recommended to be 20 to 500 feet in length.

5. Regeneration Date Proxy Feature

If the date proxy option is enabled and the valve reaches the set regeneration date, the regeneration program will start if no other valve is in regeneration status. If another valve is in regeneration status, this regeneration signal will be queued. This feature does not consider whether the remaining water production has reached zero.

6. Entering Control Program Setup Mode

-

Press and hold the up key and move key simultaneously for 5 seconds.

-

Set the time to 12:01 PM or 12:01 HR, then press and hold the up and down keys simultaneously for 5 seconds.

7. Exiting Control Program Setup Mode

1. Press the cycle key repeatedly until all options are displayed, and the screen returns to normal status.

2. To exit without saving changes, press the "D" key.

Note: In program setup mode, if no key is pressed for 5 minutes or if there is a power outage, the parameters will not be set, and the unit will return to the main display.

8. Resetting

Partial Reset:

Press and hold the up and down keys simultaneously for more than 25 seconds until 12:00 PM or 12:00 HR is displayed. All parameters except the total flow meter will be cleared.

Full Reset:

Press the move key while powering on. This will reset all parameters.